Kunal Chopra

Jul 6, 2022

The Role of Sustainability in Modern Manufacturing

How Does Sustainability Fit into Manufacturing—and Why Does It Matter?

Sustainability has become a critical element in manufacturing, where businesses face growing pressures to address environmental concerns while maintaining competitiveness. With global industries pivoting to more responsible practices, adopting green methodologies is no longer optional but essential.

This expanded guide explores the concept of sustainability in manufacturing, its numerous benefits, and actionable strategies. By integrating innovative technologies and sustainable practices, manufacturers can revolutionize their operations, align with regulations, and contribute to a brighter, greener future.

What Does Sustainability in Manufacturing Mean?

Sustainability in manufacturing combines ecological responsibility with economic practicality. It focuses on minimizing environmental impact throughout production processes while maintaining competitiveness and profitability. This approach addresses energy consumption, resource management, waste reduction, and compliance with environmental policies. It emphasizes a mindset of doing more with less—producing efficiently while caring for the planet.

Pillars of Sustainability in Manufacturing:

Environmental Responsibility

Reduce greenhouse gas emissions, conserve resources, and prevent ecosystem degradation.

Economic Sustainability

Improve cost-efficiency by streamlining processes and leveraging energy-saving innovations.

Social Impact

Promote ethical labor practices and support eco-friendly supply chains to maximize community welfare.

By adopting sustainable practices, manufacturers not only meet rising consumer expectations but also safeguard their economic future.

Why Sustainability Matters

The integration of sustainable practices has tangible, beneficial outcomes for manufacturers and the planet alike.

Environmental Benefits:

Cut Greenhouse Gas (GHG) Emissions

Transitioning to renewable energy and energy-efficient systems drastically reduces carbon footprints.

Preserve Natural Resources

Efficient use of materials and the adoption of closed systems conserve finite resources like water and minerals.

Protect Ecosystems

Sustainable production minimizes pollution and mitigates ecosystem destruction.

Economic Benefits:

Cost Savings

Optimized production processes reduce energy, water, and material waste, directly cutting operational costs.

Operational Efficiency

Lean manufacturing principles and AI-driven automation improve output rates while minimizing resource usage.

Regulatory and Customer Alignment:

Implementing sustainable systems ensures compliance with strict environmental laws, avoiding fines and improving brand trust. Consumers prefer businesses that actively demonstrate eco-consciousness.

Actionable Sustainable Practices in Manufacturing

1. Energy Efficiency

Optimizing energy strategies is one of the easiest ways to reduce your environmental impact without disrupting production.

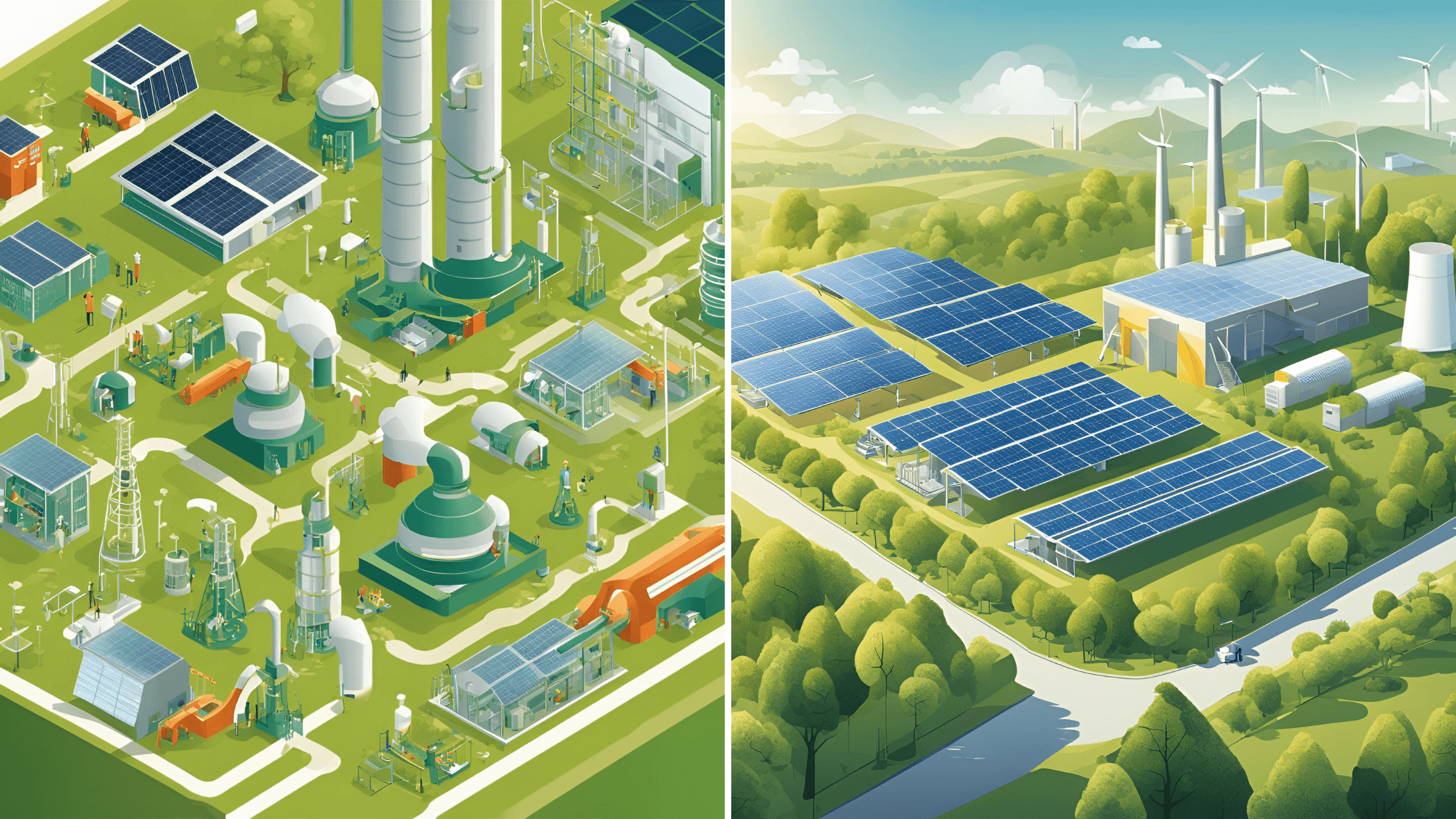

Renewable Energy Integration

Adopt solar panels, wind power, or other renewable sources to cut energy dependency on fossil fuels.

Smart Equipment

Invest in energy-efficient machinery that automatically adjusts settings in real-time to prevent wastage.

Facility Optimization

Use LED lighting, install insulation to lower HVAC energy consumption, and implement smart sensors for continuous monitoring.

Case Results: A U.S.-based manufacturer reported a 40% reduction in annual energy use after upgrading its machinery and incorporating advanced energy monitoring.

2. Waste Management and Process Optimization

Transitioning towards waste-conscious methodologies allows manufacturers to optimize material usage.

Circular Economy Adoption

Reuse materials wherever possible. Byproducts should be viewed as potential resources rather than waste.

Lean Manufacturing

Implement small-batch production or lean principles to cut overproduction, excess inventory, and waste.

Plant-wide Recycling Programs

Improve the recycling of byproducts, targeting both packaging waste and raw material scraps.

3. Water Conservation and Management

Industrial water usage introduces unique ecological challenges, but better water systems provide opportunities for optimization.

Closed-loop Systems

Recycle and reuse water across production stages.

Dynamic Filters and AI Monitoring

Detect leaks in real time and ensure treatment standards are continuously met.

Local Partnerships

Collaborate with local water authorities to adopt eco-focused policies aligned with regional challenges.

Technological Innovations Powering Green Manufacturing

Technology sits at the heart of sustainable transformation. Bold applications of innovation are accelerating enterprises toward improved eco-efficiency.

Key Innovations

Internet of Things (IoT) Integration

IoT sensors track energy usage, water consumption, emissions, and productivity in real-time.

The result? Manufacturers gain actionable insights to optimize operations continuously.

Additive Manufacturing (3D Printing)

Significantly reduces material waste by using only the precise amounts required.

Enables localized production, minimizing shipping emissions.

Artificial Intelligence (AI)

Automates decisions regarding production scheduling, energy distribution, and equipment servicing.

AI-driven systems enable predictive maintenance to prevent costly downtimes while maximizing uptime.

Blockchain Technology

Provides supply chain transparency by verifying sustainability credentials in materials and vendors.

Success Snapshot: EcoTech Solutions utilized IoT and AI systems across their facilities, cutting energy usage by an impressive 30%. Their carbon emissions dropped, costs went down, and they gained global recognition as a leader in responsible manufacturing.

Compliance & Certification Standards

Certifications provide credibility to manufacturers pursuing sustainable leadership by proving alignment with international environmental goals.

Top Certification Standards:

ISO 14001 (Environmental Management Systems)

Framework for managing operations to reduce pollution and resource waste.

LEED Certification (Green Building)

Measures energy-efficient facility design and operation.

Energy Star Certification

Validates energy-efficient, eco-friendly equipment and structures.

Certifications aren't just about compliance—they establish market trust, open global supply chain opportunities, and elevate your brand's eco-reputation.

The Business Case for Sustainability

Sustainability delivers measurable economic, operational, and strategic value.

Cost Savings

Reducing energy consumption, waste, and inefficiencies has an immediate financial upside.

Enhanced Reputation

Businesses with visible green practices appeal to eco-conscious customers and investors alike.

Stronger Investor Relationships

Green initiatives showcase long-term planning and risk mitigation, attracting investment interest.

Challenges in Implementing Sustainability

Changes that redefine operations may meet resistance or resource constraints.

Common Barriers:

Cost Concerns: High upfront costs delay investment.

Employee Pushback: Resistance to operational changes.

Complex Compliance: Navigating legally diverse regulations.

Solutions:

Focus on small, incremental innovations to reduce project complexity.

Provide sustainability training for workers and leadership teams.

Collaborate with external consultants to ensure compliance alignment.

Leadership's role is critical in driving awareness and enthusiasm throughout the transition.

Future Directions and Trends

Sustainability trends are moving fast as the global manufacturing industry embraces bold innovations.

Carbon-Neutral Factories: Powered entirely by renewable and offset energy.

Smart Product Lifecycle Models: Materials built for circular and dynamic reuse.

Digital Frameworks for Transparency: Blockchain-backed verification of responsible sourcing.

Through aligned commitments like the Paris Agreement, manufacturers are projected to make cutting-edge moves by 2035, drastically reshaping progress benchmarks.

Why You Need to Invest in Sustainability Now

Manufacturers leading the way in sustainable practices are revolutionizing their industries. By actively addressing environmental and economic efficiency, businesses reduce their ecological footprint, strengthen profitability, and gain competitive advantages.

Start by making incremental upgrades in waste management, energy use, or sustainable sourcing today. The manufacturing industry of tomorrow belongs to leaders who prioritize sustainability now. Are you ready to become an industry pioneer?

Kunal Chopra

Kunal Chopra is the CEO of Certivo, an AI-driven compliance management platform revolutionizing how manufacturers navigate regulatory challenges. With a career spanning over two decades, Kunal is a seasoned technology leader, 3x tech CEO, product innovator, and board member with a passion for driving transformative growth and innovation.

Before leading Certivo, Kunal spearheaded successful transformations at renowned companies like Beckett Collectibles, Kaspien, Amazon, and Microsoft. His strategic vision and operational excellence have led to achievements such as a 25x EBITDA valuation increase at Beckett Collectibles and a 450% shareholder return at Kaspien. He has a track record of turning challenges into opportunities, delivering operational efficiencies, and driving market expansions.

Kunal’s deep expertise lies in blending technology and business strategy to create scalable solutions. At Certivo, he applies this expertise to empower manufacturers, using AI to turn product compliance from an operational burden into a strategic advantage.

Kunal holds an MBA from The University of Chicago Booth School of Business, an MS in Computer Science from Clemson University, and a BE in Computer Engineering from The University of Mumbai. When he’s not transforming businesses, Kunal is an advocate for innovation, growth, and building cultures that inspire excellence.

Stay tuned for insights from Kunal on how technology can redefine compliance, drive efficiency, and create opportunities for growth in the manufacturing sector.